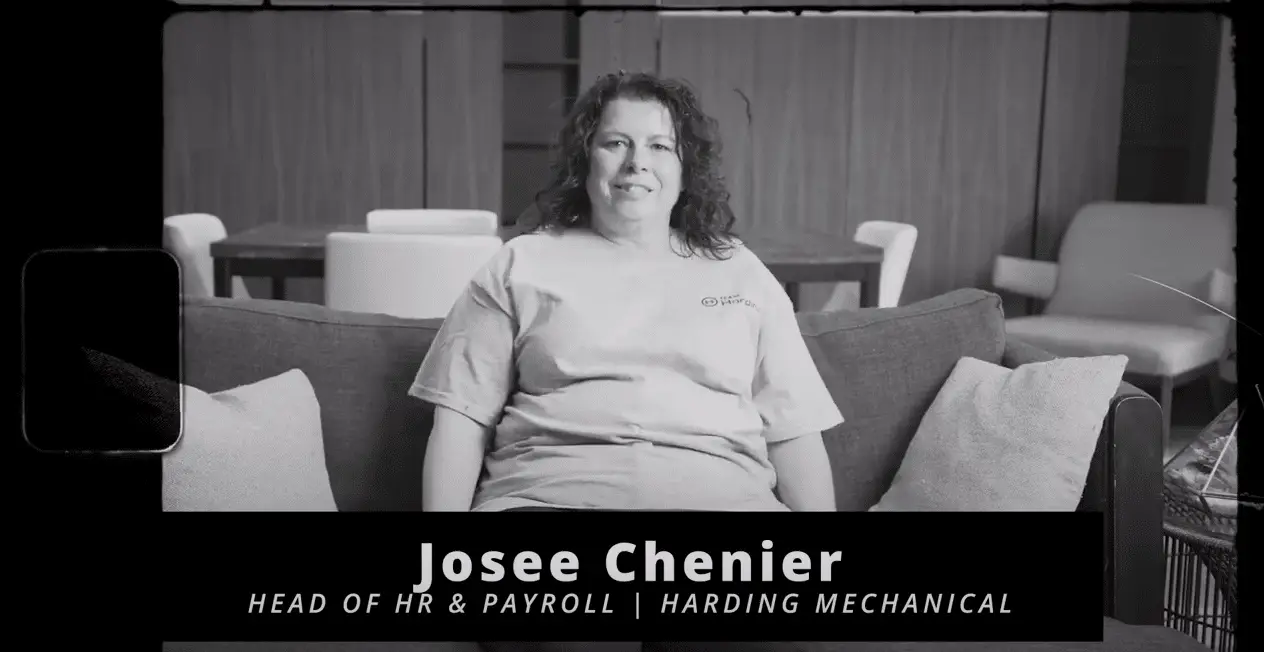

The team at Jonas Construction Software engaged in a conversation with Josee Chenier, head of HR and Payroll at Harding Mechanical to learn about their experience with Jonas’ integrated construction software and reporting tools. Read on to discover how Jonas has transformed their payroll process, improved allocation management, enhanced job cost visibility, and saved time from the field to the back office.

In this Blog:

- About Harding Mechanical

- Harding’s Main Business Concerns

- How Harding Uses Jonas

- Jonas Reporting a Game-Changer for Harding

- How Jonas Helps in Managing Misallocation Risk

- Jonas’ Role in Tracking Job Costs

- How Jonas Supports Efficiency for Harding’s Service Side

- Harding’s Evolution With Jonas Over the Years

- Why Harding Continues to Use Jonas Construction Software

Could you start by telling us about yourself and your business?

JC: I’m Josee Chenier and I work for Harding Mechanical. I am the head of HR and payroll. We’ve been using Jonas since 2001.

We are an HVAC company, so we install heating and cooling in new homes. We also have a retrofit division and a service division. In the service division, we do servicing, repairs, maintenance and service contracts. In retrofit, [we serve] customers who want to renovate their homes. We do hire sub-trades as well.

Ours is a family-oriented business. Both the owners will give the shirt off their backs to anyone. We have great workers, and everyone cares for one another.

What would you consider your top business concerns to be?

JC: [Job cost] allocations, and making payroll error-free are my main concerns. Making sure that everyone gets paid on time is another one. When Friday comes, everyone is paid and we don’t hear anyone calling us and everything looks good. It’s like “Wooo, error free!”

Would you walk us through how you manage work in the field and the accounting in the back office?

JC: When we get a project, it’s for a specific site. The site is an area. One lot is one house. So that means there could be 20 houses, 30 houses, or 100 hundred houses on a site. And we take care of all their HVAC needs. It could take us a year to be on that site, or sometimes maybe six months.

As soon as we get the tender, we contact the foreman, telling him his site is ready. Once it’s ready for us to start the heating and cooling, the foreman arranges to start creating a material list for our sub-trades.

Once that is done, payroll gets involved. After payroll is closed, job costing gets involved because they know through Data Mart — a reporting tool within Jonas — that they have the ability to see exactly what was done, which they bill the builder.

As well, the [Jonas] material module links to the lot. We know exactly how much the material costs are for that lot and what material actually was used.

Could you describe how you and the team use Jonas?

JC: Since we started with Jonas in 2001, we implemented a lot of modules like general ledgers, accounts payable, accounts receivable, inventory, PO and payroll, service billing, job costing, and eMobile.

In what ways does Jonas construction reporting help you to manage your responsibilities?

JC: [Jonas] Data Mart has been a game-changer for Harding. We were so happy when we were introduced to it at a [Jonas customer] conference. We create our own reports and we use it for every department, for allocations, and for tracking.

Data Mart and [Jonas] EBI (Enterprise Business Intelligence) as a combination will be a huge game-changer for Harding. For us, it’s very important to have reports that are live in real-time, and I think EBI will give that to us.

When it comes to allocations, how does the software help you with decreasing misallocation?

JC: We don’t think anybody is mistake-free. Everyone will make mistakes. But then, it is very important for us to have the right cost. For us, it is important to catch all the misallocations for financial analysis, and we use [Jonas] Data Mart for that.

When misallocation happens, we use Data Mart reporting to help us [locate the cause]. We then use the general ledgers to allocate them to the right location. When we reallocate the cost to the proper job, we see a difference in the bottom line of the project, and it does show proper financial numbers.

Can you elaborate on how the software helps you track costs?

JC: [Jonas] Data Mart allows us to find the proper cost to tender on the next project, with the right amounts for a profit. When a project is completed, we are able to check all the lots to see if the costs are somewhat the same by model.

Data Mart helps us by doing a report that shows the material and labor costs. And it leads us to an investigation – why it would cost us more to do one lot than another one when the houses are the same model.

When that happens it could be a misallocation. We find out where the cost should have been and then we do an allocation. Sometimes, the wrong-size furnace goes out and we have to get a change order to get our funds back from the builder.

Would you mind talking about how you use work orders on the service side of your business?

JC: Work orders are for service, retrofit and cleaning, and maintenance. Say a customer calls because his furnace is not working. We make up a work order. Their information goes into the accounts receivable, which is pulled to the work order. The work order then gets attached to the Dispatch Scheduler, and the dispatcher lets our technician know exactly where to go to fix the issue.

If he’s using [Jonas] eMobile, he will use the tablet instead of writing all the information down. And if there’s a payment required, they have a machine through which the funds come to Harding.

As an Enterprise software, what’s it like to use Jonas?

JC: Even though there’s a lot of training that has to get done [for Jonas], once you know Jonas, it’s very easy.

Could you speak about how our businesses have evolved together over the years?

JC: We’ve been in business since 2001 and Harding has been growing ever since. Bigger, bigger every year. More customers and a lot of growth, meaning a lot more employees, and subcontractors.

Every time that we grew, Jonas grew as well. [As] more modules came out, the more excited we were. We were able to implement modules that made us more profitable, and I think that’s one of the main reasons why we stayed with Jonas.

If Jonas didn’t keep growing and our company kept growing, we would have outgrown Jonas.

Is there anything else you’d like to share?

JC:. Jonas helps us make sure everything is allocated properly. It helps us track, it helps us make reports, and it helps us find profits.

After 22 years, I think we’ll be keeping Jonas for a little while longer.

To learn more about Jonas Construction or any of the features shared in this Q&A, contact us today and discover how Jonas can help you increase operational efficiency, enhance cash flow predictability and identify profit fade for projects and contracts.